Processing, packaging, and exporting bananas and plantains involve several important steps to ensure the fruits reach international markets in good condition.

Processing Bananas and Plantains starts with harvesting the fruits when they are mature but still green. This helps them ripen properly during transportation.

After harvesting, the fruits are washed to remove dirt and residues. Sorting follows, where fruits are categorized based on size, weight, and quality, with any damaged ones discarded.

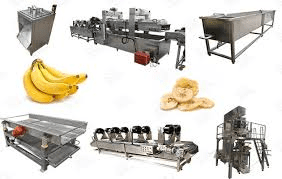

Depending on the market, ripening may be necessary and can be accelerated using controlled ripening rooms with ethylene gas. Once ripened, the fruits are cooled to slow down the ripening process. For processed products, such as banana chips or plantain flour, peeling, cutting, blanching, and drying are required.

Blanching helps preserve color and texture, while drying extends shelf life. If producing flour, the dried plantains are ground into a fine powder. Packaging involves placing the processed products in air-tight containers, using vacuum-sealed bags for freshness, and clearly labeling with product details. Quality control is essential at each stage to meet export standards.

Packaging Bananas and Plantains for export begins with selecting high-quality materials like corrugated cardboard boxes or wooden crates. Packaging materials should be pre-cooled to avoid heat damage.

Fruits are layered with cushioning materials to prevent bruising and ensure proper ventilation. Packages are sealed securely to prevent moisture loss and contamination, with each package labeled with the product name, quantity, and handling instructions.

The packaged fruits are then placed on pallets, secured with shrink wrap, and transported in refrigerated containers if needed. Final inspection ensures that all packages meet export standards, and that necessary documentation, including phytosanitary certificates and packing lists, is prepared.

Exporting Bananas and Plantains profitably involves thorough market research to understand demand, competition, and pricing. Compliance with export and import regulations, including phytosanitary standards, is crucial. Securing a reliable source of high-quality fruits and determining competitive pricing based on market conditions is key.

Logistics planning, including choosing reliable freight forwarders and transport methods, is essential. Contracts with buyers should outline terms of sale, payment, and quality standards.

Ensuring favorable payment terms and insuring the shipment against risks are also important. Monitoring the shipment and maintaining good customer relations through consistent communication help ensure successful export operations.

Understanding these steps helps ensure bananas and plantains are processed, packaged, and exported efficiently, meeting market demands and maintaining high quality throughout the supply chain.

How to Process Bananas and Plantains for Exportation

1. Harvesting: Harvest bananas and plantains when they are mature but still green. This ensures they ripen during transportation.

2. Washing: Clean the fruits thoroughly with clean water to remove any dirt, pesticides, or residues. Use a gentle brush if necessary.

3. Sorting: Sort the fruits based on size, weight, and quality. Discard any that are bruised, damaged, or diseased.

4. Ripening: For some markets, you may need to ripen bananas before shipping. Use controlled ripening rooms with ethylene gas to speed up the process.

5. Cooling: Cool the fruits immediately after ripening to slow down the ripening process. This helps maintain their quality during transport.

6. Peeling and Cutting (if necessary): For processed products like banana chips or plantain flour, peel and cut the fruits into the desired shapes and sizes.

7. Blanching (for chips): Blanch the sliced fruits in hot water for a few minutes. This step helps preserve their color and texture.

8. Drying: Dry the fruits using a dehydrator or oven to remove moisture, which helps extend shelf life and reduce shipping weight.

9. Grinding (for flour): Grind the dried plantains into a fine powder if producing plantain flour. Ensure the flour is free from lumps and contaminants.

10. Packaging: Pack the processed products in air-tight containers to prevent moisture and contamination. Use vacuum-sealed bags for extended freshness.

11. Labeling: Clearly label the packages with product details, including weight, ingredients, and expiration date.

12. Quality Control: Perform quality checks at each stage to ensure the products meet export standards and customer expectations.

Read Also: Egg Formation and Production Process (From Day-Old to First Lay)

How to Package Bananas and Plantains for Exportation

1. Selecting Packaging Materials: Use high-quality packaging materials like corrugated cardboard boxes, wooden crates, or plastic containers to protect the fruits during transport.

2. Pre-cooling Packaging: Ensure that packaging materials are pre-cooled to avoid heat damage to the fruits.

3. Layering: Place a cushioning material like foam or paper between layers of fruits to prevent bruising.

4. Ventilation: Use packaging that allows for proper ventilation to prevent overheating and maintain air circulation around the fruits.

5. Sealing: Seal the packages securely to prevent moisture loss and contamination. Use strong adhesive tapes or strapping.

6. Labeling: Label each package with the product name, quantity, weight, and handling instructions. Include export and import documentation as required.

7. Palletizing: Place the packaged fruits on pallets to make handling and transport easier. Secure the packages with shrink wrap to keep them in place.

8. Temperature Control: Use refrigerated containers for shipping if necessary to maintain the optimal temperature for the fruits.

9. Inspection: Conduct a final inspection to ensure all packages are secure and meet export standards.

10. Documentation: Prepare all necessary export documentation, including phytosanitary certificates, commercial invoices, and packing lists.

How to Export Bananas and Plantains for Profits

1. Market Research: Research potential markets to identify demand, competition, and pricing for bananas and plantains.

2. Compliance: Ensure compliance with both the exporting country’s regulations and the importing country’s requirements, including phytosanitary standards.

3. Sourcing: Secure a reliable source of high-quality bananas and plantains to ensure consistency in supply.

4. Pricing: Determine competitive pricing based on market research, production costs, and desired profit margins.

5. Logistics: Plan logistics for shipping, including choosing reliable freight forwarders and transport methods.

6. Contracts: Establish contracts with buyers outlining terms of sale, payment, delivery, and quality standards.

7. Payment Terms: Negotiate favorable payment terms with buyers, such as letters of credit or advance payments to ensure cash flow.

8. Insurance: Insure the shipment against potential risks such as damage, loss, or delays.

9. Monitoring: Track the shipment to ensure timely delivery and address any issues that arise during transit.

10. Customer Relations: Maintain good relationships with buyers through consistent communication and quality assurance.

Read Also: How to Identify Poultry Sick Birds and Cure Them

Frequently Asked Questions (FAQ’s) About Bananas and Plantains

1. What are the main differences between bananas and plantains?

Bananas are typically sweeter and eaten raw, while plantains are starchy and usually cooked before eating.

2. How are bananas and plantains harvested?

They are harvested when mature but still green to ensure they ripen during transport.

3. What is the best way to store bananas and plantains for export?

Store them in a cool, dry place with proper ventilation to prevent overheating and spoilage.

4. Can bananas and plantains be processed into other products?

Yes, they can be processed into products like banana chips, plantain flour, and dried fruit.

5. What are the common packaging methods for export?

Common methods include using corrugated cardboard boxes, wooden crates, or plastic containers with proper ventilation.

6. How is the quality of bananas and plantains ensured during export?

Quality is ensured through sorting, ripening control, cooling, and regular quality checks.

7. What documentation is needed for exporting bananas and plantains?

Required documentation includes phytosanitary certificates, commercial invoices, packing lists, and export/import permits.

8. What are the major markets for exporting bananas and plantains?

Major markets include North America, Europe, and parts of Asia, where demand for these fruits is high.

9. How do exporters deal with the ripening process during transport?

They use refrigerated containers and control the temperature to slow down the ripening process.

10. What are the risks involved in exporting bananas and plantains?

Risks include spoilage, delays, damage during transport, and changes in market demand.

Read Also: The Importance of Ethics in Business